Slow primary fermentation in beer can be caused by several factors. Ethanol buildup above 5% can stress yeast, leading to slower fermentation. If you use complex sugars, yeast may struggle to process them. Nutrient deficiencies, particularly nitrogen, can hinder yeast performance. Temperature fluctuations also affect yeast activity; keeping your fermentation temperature steady is essential. Additionally, not pitching enough yeast can slow down the process. To improve your brewing outcome, consider monitoring these aspects for better fermentation results.

At a Glance

- High ethanol levels around 5% can stress yeast, slowing fermentation as they prioritize simpler sugars over complex ones.

- Complex and unfermentable sugars can hinder yeast activity, causing sluggish fermentation if not adequately managed.

- Nutrient deficiencies, particularly nitrogen, are crucial for yeast health and can lead to stalled fermentation if not monitored.

- Sudden temperature fluctuations can stress yeast, negatively impacting fermentation; maintaining ideal temperatures is essential.

- Excess sediment and insufficient yeast pitch can inhibit yeast activity, slowing fermentation and resulting in off-flavors.

Understanding Ethanol Buildup and Its Effects on Yeast Activity

When you brew beer, you should be aware that ethanol buildup can greatly impact yeast activity. When ethanol concentration reaches around 5%, yeast cells experience stress, which slows their fermentation process.

They consume simpler sugars first, but as fermentation progresses, more complex sugars remain, making it harder for yeast to maintain activity. Different yeast strains react uniquely to ethanol, affecting the overall brewing outcome.

Regularly monitoring specific gravity allows you to track fermentation progress and identify potential issues. Understanding these factors helps you innovate your brewing process, ensuring that your beer achieves the desired flavor and quality.

Helpful Hints

- Monitor specific gravity consistently.

- Experiment with different yeast strains.

- Control ethanol levels to reduce stress.

The Role of Sugar Types in Fermentation

Understanding the types of sugars present in your wort is vital for managing fermentation speed. Yeast prefers fermentable sugars like glucose and maltose, which it consumes quickly. In contrast, complex sugars and unfermentable sugars, such as dextrins, can slow down fermentation.

Understanding the sugar composition in your wort is crucial for optimizing fermentation speed and yeast activity.

As fermentation progresses, yeast first utilizes easier sugars, leaving complex ones that require more energy. High sugar concentrations can create osmotic stress, inhibiting yeast activity. Consequently, monitoring specific gravity is essential; a decline indicates active fermentation, while stagnation may signal yeast struggling with remaining sugars. Additionally, maintaining an optimal mash pH range is crucial for ensuring yeast health and fermentation efficiency.

By understanding these dynamics, you can optimize your brewing process for faster fermentation.

Helpful Hints

- Use simple sugars to speed up fermentation.

- Monitor specific gravity regularly.

- Consider sugar types when formulating your wort.

Nutrient Deficiencies and Their Impact on Yeast Performance

Nutrient deficiencies can greatly impact yeast performance during fermentation, leading to slower processes or even complete stalls.

Yeast requires essential nutrients, particularly nitrogen, to thrive. Without adequate yeast nutrients, you’ll likely encounter sluggish fermentation and reduced fermentation rates.

Regular monitoring of fermentation metrics, like gravity readings, helps you identify potential issues early. If you notice your specific gravity isn’t decreasing as expected, consider using a homemade yeast nutrient mix that includes crucial components such as zinc.

Addressing nutrient deficiencies promptly can markedly enhance yeast performance and prevent fermentation issues, ensuring a successful brewing experience. Additionally, ensuring proper yeast management practices can further support yeast vitality and minimize fermentation challenges.

Temperature Control: Maintaining Optimal Conditions for Fermentation

Temperature control plays a pivotal role in fermentation, as maintaining ideal conditions directly impacts yeast performance and beer quality.

For peak fermentation, consider these helpful hints:

- Monitor Your Yeast Strain: Ale yeasts thrive between 16°C to 20°C (60°F to 68°F), while lager yeasts prefer cooler conditions of 7°C to 13°C (45°F to 55°F).

- Prevent Fluctuations: Sudden temperature changes can stress yeast, causing sluggish fermentation or unwanted off-flavors.

- Utilize Control Methods: Employ fermentation jackets or regulated chambers to maintain steady temperatures, ensuring peak yeast activity and a superior beer profile. Additionally, maintaining a stable, strain-appropriate temperature range during fermentation is essential to avoid yeast stress and ensure optimal fermentation performance.

Importance of Yeast Pitching Rates in Successful Fermentation

Yeast pitching rates greatly influence the success of fermentation, making it essential to get this step right for ideal beer production.

Insufficient yeast cells lead to slow fermentation, as there aren’t enough microorganisms to efficiently consume sugars. Use a yeast calculator to determine the right pitching rate based on the original gravity of your wort; higher gravities require more yeast cells.

Insufficient yeast cells can slow fermentation, so use a yeast calculator to determine the ideal pitching rate for your wort’s gravity.

Aim for 0.75 to 1 million cells per milliliter per degree Plato. Be cautious of over-pitching yeast, which can hinder yeast health and the fermentation process, ultimately affecting your final gravity. Additionally, selecting the right yeast strain for your specific beer style can further enhance fermentation efficiency.

Monitor yeast health for best results.

Monitoring Specific Gravity for Early Detection of Issues

How can you guarantee your fermentation process is on track? Monitoring specific gravity is essential for early detection of issues. Regular readings, ideally every 48-72 hours, can reveal stagnation. Use a hydrometer or refractometer for accurate measurements.

Helpful Hints:

- Start with your original gravity (O.G) reading, here 1.059, and track your final gravity (F.G), targeting 1.018 for desired ABV.

- Watch for significant drops; a lack of change, like reaching only 1.034 by Day 6, signals potential problems.

- Investigate causes like yeast health, nutrient deficiencies, or temperature fluctuations affecting fermentation.

- Tracking original gravity readings can help you understand how fermentation is progressing and whether adjustments are needed.

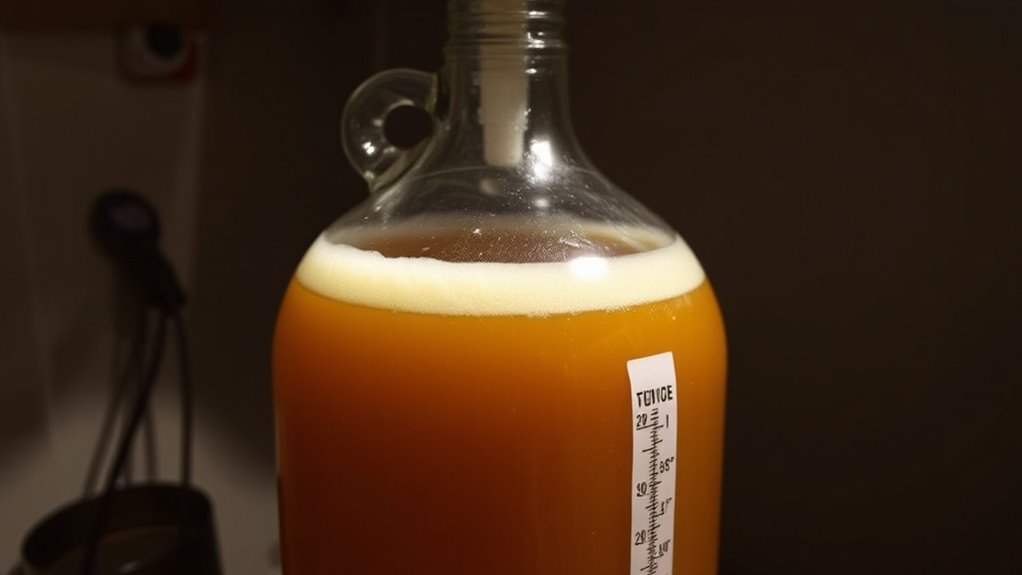

The Effects of Oxygen Exposure During Fermentation

When brewing beer, maintaining an anaerobic environment is essential for successful fermentation. Oxygen exposure can lead to off-flavors, such as stale or cardboard-like tastes, which negatively impact your beer’s quality.

Yeast thrives in anaerobic conditions, and when exposed to oxygen, it may produce undesirable fusel alcohols and esters, resulting in slower fermentation. Additionally, introducing oxygen can stress yeast, potentially causing stalled fermentation. Prolonged oxygen exposure can also promote the formation of reactive oxygen species, further compromising the flavor and quality of your beer.

Yeast flourishes in anaerobic conditions; oxygen exposure can lead to off-flavors and stalled fermentation.

To prevent these issues, securely seal fermentation vessels with airlocks, allowing carbon dioxide to escape while keeping oxygen out. Remember, minimizing oxygen exposure also reduces the risk of microbial contamination, ensuring a healthier fermentation process.

Helpful Hints:

- Always check seals on fermentation vessels.

- Monitor airlock activity regularly.

- Avoid opening vessels during fermentation.

Identifying and Addressing Sediment Buildup

Understanding the impact of sediment buildup during fermentation is essential for ensuring a successful brewing process. Excess sediment can inhibit yeast activity, slow fermentation progress, and lead to off-flavors.

Helpful Hints:

- Regularly monitor sediment levels to gauge yeast health and fermentation progress.

- Racking to a new vessel can reduce sediment’s negative impact, allowing yeast to thrive.

- If fermentation stagnates, consider adding fresh yeast after racking to reinvigorate the process.

Troubleshooting Common Fermentation Problems

Troubleshooting common fermentation problems is crucial for achieving a successful beer.

Start by ensuring you have an adequate yeast pitch; insufficient yeast can hinder high gravity brews.

Ensure your yeast pitch is adequate; too little yeast can impede your high gravity brewing efforts.

Keep an eye on temperature fluctuations, as excessive heat can cause ethanol stress, slowing fermentation rates.

Nutrient deficiencies, particularly nitrogen, can reduce yeast vigor, so consider adding yeast nutrients to your wort.

Regularly check specific gravity readings; if they remain unchanged for 48-72 hours, your fermentation may be stalled.

Additionally, maintaining thorough cleaning and sanitation practices can help prevent contamination that might slow down fermentation.

Address these issues promptly to maintain a healthy fermentation process and produce the innovative beers you aspire to create.

1 comment

Comments are closed.