To control secondary fermentation temperature, maintain a steady range between 68°F and 75°F. This temperature stability enhances yeast activity and flavor development. Avoid drastic fluctuations, as they can lead to unwanted flavors. Monitor the temperature regularly, and adjust gradually if needed. Helpful hints: 1) Use a thermometer for accurate readings; 2) Place your fermenter in a regulated environment; 3) Consider using Kveik yeast, which operates well at higher temperatures. Understanding these factors can greatly improve your brewing outcomes.

At a Glance

- Maintain a steady temperature between 68°F to 75°F to ensure optimal yeast activity and flavor development during secondary fermentation.

- Regularly monitor temperature to avoid drastic fluctuations that can negatively impact beer quality and introduce off-flavors.

- Gradually adjust temperatures to prevent yeast stress and maintain consistent fermentation activity throughout the conditioning phase.

- Avoid temperatures below 59°F to ensure active yeast and prevent hindrance in fermentation progress and clarity.

- Sanitize all equipment before use to prevent contamination, which can affect fermentation and overall beer quality.

Importance of Temperature Control in Secondary Fermentation

When you’re brewing beer, understanding the importance of temperature control during secondary fermentation can greatly impact the final product.

While yeast activity decreases, maintaining a steady temperature between 68-74°F guarantees ideal conditioning and flavor development. Allowing the temperature to rise to around 72°F can enhance quality by promoting a cleaner profile and better attenuation.

Maintaining a steady temperature of 68-74°F during secondary fermentation ensures optimal conditioning and enhances flavor development.

Even temperatures up to 75°F can improve yeast activity, leading to improved carbonation and clarity. Remember, fluctuations in temperature are more forgiving during secondary fermentation than in the vital first 72 hours of primary fermentation. Additionally, maintaining a stable, strain-appropriate temperature range helps prevent unwanted esters that can negatively affect flavor.

Helpful Hints:

- Monitor temperature regularly.

- Avoid drastic changes.

Ideal Temperature Range for Secondary Fermentation

Ideal Temperature Range for Secondary Fermentation****

The ideal temperature range for secondary fermentation is vital for achieving high-quality beer, typically falling between 68°F and 75°F (20°C to 24°C). This fermentation temp encourages yeast activity, improving clarity and flavor.

While secondary fermentation can tolerate broader temperatures, maintaining consistency is important; fluctuations may impact aroma and flavor, though they’re less critical than in primary fermentation. Higher temperatures can enhance flavor and promote cleaner beer. Monitoring fermentation, including specific gravity, is essential to ensure the process is on track for optimal results.

For effective conditioning and carbonation, keep your beer around room temperature after primary fermentation.

Helpful Hints:

- Aim for steady temperatures.

- Monitor your fermentation closely.

Effects of Temperature Fluctuations on Beer Quality

Temperature fluctuations can greatly impact the quality of your beer during secondary fermentation. Maintaining a steady fermentation temperature between 68-74°F guarantees a cleaner, more refined product.

If temperatures rise gradually, yeast strain activity increases, enhancing flavor development. Conversely, cold temperatures can slow yeast activity, extending conditioning time and affecting clarity and carbonation.

Higher temperatures, up to 75°F, can promote full attenuation, yielding a smoother beer without adverse flavor effects. To optimize your brew, monitor your fermentation temperature closely and avoid drastic fluctuations, as they can introduce undesirable characteristics that compromise your beer’s quality. Additionally, maintaining consistent brew kettle temperature is crucial for achieving the desired balance of flavors and sugars throughout the brewing process.

Helpful Hints:

- Use a thermometer to track temperature.

- Insulate your fermentation vessel.

Managing Temperature During the Conditioning Phase

Managing the temperature during the conditioning phase is essential for achieving a high-quality beer. To optimize fermentation and flavor, consider these helpful hints:

- Maintain a temperature between 72°F to 75°F to enhance yeast activity and improve conditioning.

- Keep temperatures consistent, as fluctuations can negatively affect aroma and flavor profiles.

- Avoid temperatures below 59°F, which can hinder yeast activation and carbonation.

- Cold crashing can clarify your beer, but monitor fermentation temperatures carefully to avoid stalling yeast activity.

Techniques for Temperature Stability in Homebrewing

When it comes to ensuring temperature stability during secondary fermentation, employing specific techniques can make a significant difference in your homebrewing process. Aim to keep your fermentation temperature between 68-74°F (20-23°C) for ideal flavor development.

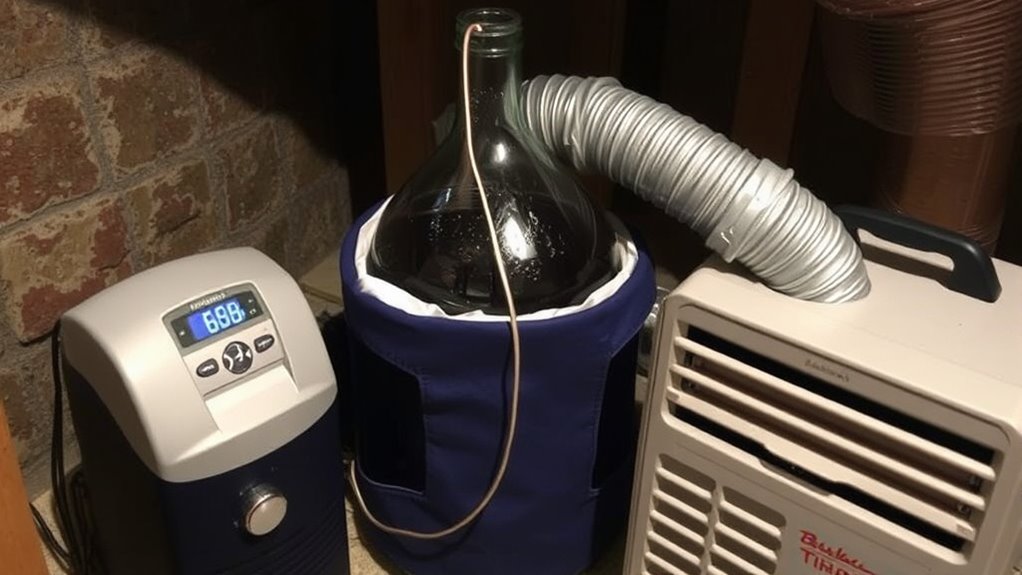

- Water Bath: Use a water bath with a heater for gradual temperature control.

- Heating Pad: If it’s too cold, place the fermenter on a heating pad, ensuring it doesn’t exceed 75°F (24°C).

- Digital Thermometer: Monitor the temperature with a digital thermometer for real-time adjustments.

Avoid drastic temperature shifts when shifting from primary to secondary fermentation to reduce yeast stress.

Using Kveik Yeast for Temperature Flexibility

Kveik yeast stands out as a versatile option for homebrewers seeking flexibility in fermentation temperatures. This unique strain allows you to ferment effectively even at elevated temperatures, providing several advantages:

Kveik yeast offers homebrewers exceptional flexibility, thriving in high temperatures for efficient and clean fermentation.

- High Temperature Tolerance: Kveik can handle temperatures up to 90°F (32°C) without off-flavors.

- Rapid Fermentation: It often completes fermentation in just a few days, shortening brewing cycles.

- Forgiving Nature: Unlike other yeasts, Kveik thrives in a wider temperature range, simplifying the brewing process.

- Clean Flavors: Historical selection ensures clean flavor profiles, perfect for warmer climates.

Embrace Kveik for unmatched temperature adaptability.

Benefits of Higher Temperatures in Secondary Fermentation

Higher temperatures during secondary fermentation can greatly enhance the quality of your beer. By raising the temperature to around 72-75°F, you encourage complete attenuation of sugars, resulting in a cleaner beer without negative flavors.

This higher temperature also boosts yeast activity, improving clarity and flavor integration. Furthermore, it aids in mitigating any residual off-flavors from primary fermentation, leading to a more refined product.

Additionally, warmer conditions can reduce fermentation time, getting your beer ready for bottling or kegging sooner. Proper yeast management practices are essential to maximize the benefits of this approach.

Helpful Hints:

- Experiment with temperatures within the 72-75°F range.

- Monitor yeast activity closely for ideal results.

Monitoring and Adjusting Temperature Effectively

To achieve the best results during secondary fermentation, it’s essential to monitor and adjust the temperature effectively.

Here are some helpful hints for ideal temperature control:

- Maintain a temperature range of 68-74°F (20-23°C) to enhance yeast activity.

- Gradually increase the temperature by about 5°F (2.8°C) post-primary fermentation for better attenuation.

- Use a thermometer or temperature controller to consistently monitor your fermentation environment.

- If needed, utilize a fish tank heater or temperature-controlled mini fridge to maintain the desired temperature during secondary fermentation.

These steps will help you achieve a well-conditioned beer with enhanced flavor and aroma.

Common Mistakes to Avoid in Temperature Management

When managing temperature during secondary fermentation, it’s important to be aware of common mistakes that can impact your beer’s quality.

- Fluctuating Temperatures: Unlike primary fermentation, secondary allows for some temperature variation. Don’t stress over strict temperature control.

- Rapid Temperature Changes: Avoid increasing temperature too quickly; gradual adjustments keep yeast activity steady and prevent off-flavors.

- Racking Too Early: Wait until primary fermentation is complete to prevent oxygen exposure and disrupt yeast settling.

- Ignoring Monitoring: Keep temperatures within 68-74°F.

- Overlooking Yeast Activity: Verify yeast remains active for proper carbonation and flavor development. Additionally, ensure that all equipment is properly sanitized to avoid introducing microbes that could affect fermentation outcomes and beer quality, as sanitizing brewing equipment is critical in maintaining the integrity of your brew.