Sanitizing brewing equipment before every batch is essential for preventing spoilage and off-flavors in your beer. Harmful microorganisms, like wild yeast and bacteria, can thrive on unclean surfaces, compromising your brew’s quality. Use effective sanitizers, such as acid-based options like Star San, and guarantee thorough coverage of all surfaces. Clean equipment prevents biofilm buildup, maintaining your beer’s flavor and stability. By following these practices, you’ll safeguard your brewing process and achieve better results. Learn more about effective sanitization methods and best practices.

At a Glance

- Sanitizing eliminates harmful microorganisms, preventing spoilage and off-flavors in your beer.

- It ensures consistency and quality by safeguarding against contamination during the brewing process.

- Sanitation helps maintain the stability of the beer, preserving its intended flavors.

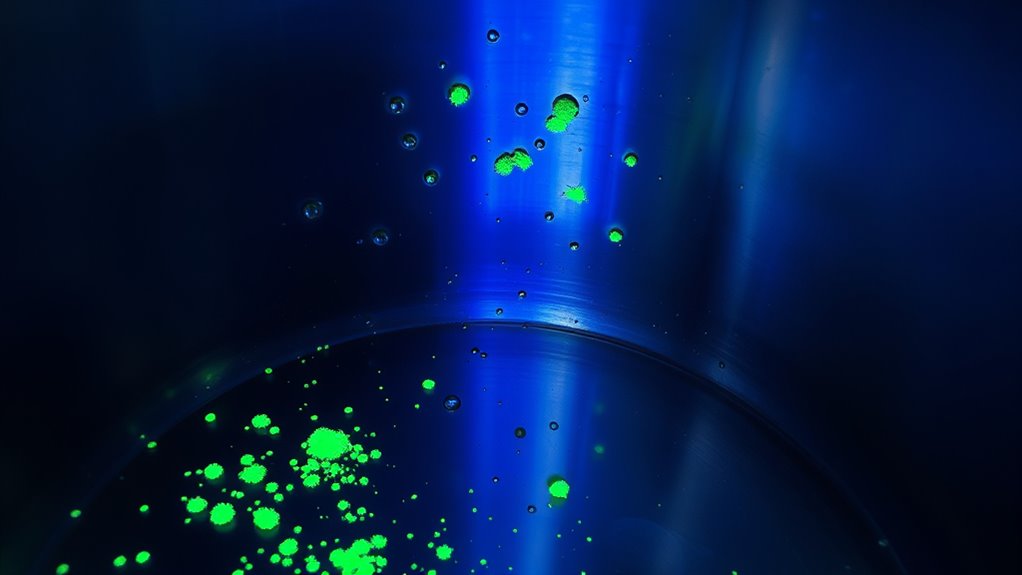

- Regular sanitization protects against biofilm buildup in fermentation vessels, which can harbor bacteria.

- Proper sanitization practices start with clean equipment, ensuring effective microbial control.

The Importance of Sanitizing Brewing Equipment

Sanitizing brewing equipment is crucial because it directly impacts the quality of your beer. Proper cleaning and sanitation eliminate harmful microorganisms, including wild yeast and bacteria, that spoil your brew.

Residual contaminants can carry unwanted flavors, compromising consistency. To achieve effective sanitization, start with clean equipment; any dirt can harbor microbes, undermining your efforts.

Residual contaminants can introduce unwanted flavors, jeopardizing consistency; always begin with clean equipment to prevent microbial issues.

Use specific sanitizing products, like Star San or Iodophor, ensuring surfaces are treated adequately. Remember, maintaining proper contact time for each sanitizer is essential for hygiene. Chemical sanitizers are effective solutions that help ensure your equipment is free from contamination.

By prioritizing these practices, you’ll safeguard your beer’s flavor and stability, leading to superior brewing results every time.

Helpful Hints

- Always pre-clean surfaces before sanitizing.

- Choose the right sanitizer for your equipment.

- Follow manufacturer instructions for contact time.

Common Types of Sanitizers and Their Uses

When it comes to brewing beer, understanding the common types of sanitizers and their specific uses is essential for maintaining quality.

Here are four effective options you might consider:

- Oxygen-based: Easy to use, requires 2 minutes contact time, great for cleaning and sanitizing.

- Iodine-based: Quick 30 seconds contact time but check concentration to avoid staining.

- Sodium metabisulfite: Simple, 1-minute contact time, effectiveness may be hard to verify.

- Acid-based (Star San): Requires 30 seconds on clean equipment; check pH for effectiveness.

Using the right sanitizer products is crucial to ensure optimal results in your brewing process. Always follow manufacturer guidelines for ideal cleaning and sanitizing throughout your brewing process.

Cleaning Versus Sanitization: Understanding the Difference

Understanding the difference between cleaning and sanitization is essential for successful brewing. The cleaning process involves removing visible dirt and residues from surfaces, while effective sanitization kills harmful microorganisms on those cleaned surfaces.

If you don’t clean first, residual soils can survive the sanitizing process, leading to off-flavors. Different cleaning agents serve specific purposes; for example, alkali detergents break down organic material, whereas acid cleaners tackle inorganic residues.

Always remember to thoroughly rinse after cleaning. To achieve a quality brew, you must both clean and sanitize your equipment, ensuring a safe and enjoyable brewing experience. Thorough cleaning is crucial in preventing wild yeast contamination.

Helpful Hints:

- Always clean before sanitizing.

- Use appropriate cleaning agents.

- Adhere to sanitizer contact times.

Best Practices for Effective Sanitization

Effective sanitization is essential for successful brewing, as it directly impacts the quality of your final product.

To guarantee your brewing equipment is thoroughly sanitized, follow these best practices:

- Always sanitize immediately before use to eliminate potential contaminants.

- Choose effective sanitizers based on required contact time, like iodine-based options that need just 30 seconds.

- Ensure thorough coverage of all surfaces by soaking, spraying, or shaking sanitizers.

- Avoid ineffective options, such as oxygen-based sanitizers, in spray form.

Additionally, regular cleaning of fermentation vessels is crucial to prevent biofilm buildup that can compromise your brewing process.

Equipment Maintenance and Handling Tips

Sanitizing your brewing equipment sets the foundation for quality beer, but maintaining that equipment is just as important.

To prevent contamination, always sanitize all items that touch wort or beer. Follow a consistent cleaning regimen, and use sanitized hands or gloves when handling these items.

Always sanitize items that contact wort or beer, and maintain cleanliness with sanitized hands or gloves.

Regular maintenance is essential; inspect your brewing equipment frequently and replace any worn parts to avoid harboring microbes.

Store sanitized equipment in a dust-free, dry area to keep it clean until use.

Troubleshooting Common Sanitization Issues

When you encounter issues with sanitizing your brewing equipment, it’s essential to pinpoint the underlying problems to confirm a successful brewing process.

Consider these troubleshooting tips to address potential sanitation failures:

- Always thoroughly rinse equipment after using any cleaning solution.

- Verify the proper dilution of your sanitizer to confirm effective microbial kill rates.

- Check that you adhere to the required contact time for each sanitizer.

- Monitor temperature fluctuations, as many sanitizers work best within specific ranges.

- Ensure that you are sanitizing only the caps that will be used immediately to maintain the integrity of the caps in the brewing process.

6 comments

Comments are closed.