If your fermentation airlock isn’t bubbling, it could be due to several factors. First, check if fermentation is complete; a stable specific gravity over a few days indicates this. Next, inspect the seal; gas might escape unnoticed if it’s loose. Also, temperature fluctuations can slow yeast activity. Finally, verify your yeast is healthy and adequately aerated. If these issues persist, consider re-pitching fresh yeast to revive fermentation. By troubleshooting these factors, you can enhance your fermentation process further.

At a Glance

- The fermentation may be complete, leading to no additional CO2 production and thus no bubbling in the airlock.

- A tight seal is crucial; any leaks can allow gas to escape without bubbling.

- Temperature fluctuations can slow yeast activity, impacting fermentation and airlock function.

- High sugar content might overwhelm yeast, resulting in stalled fermentation and reduced airlock activity.

- Check specific gravity; stable readings indicate fermentation completion despite lack of bubbling.

Understanding Airlock Functionality

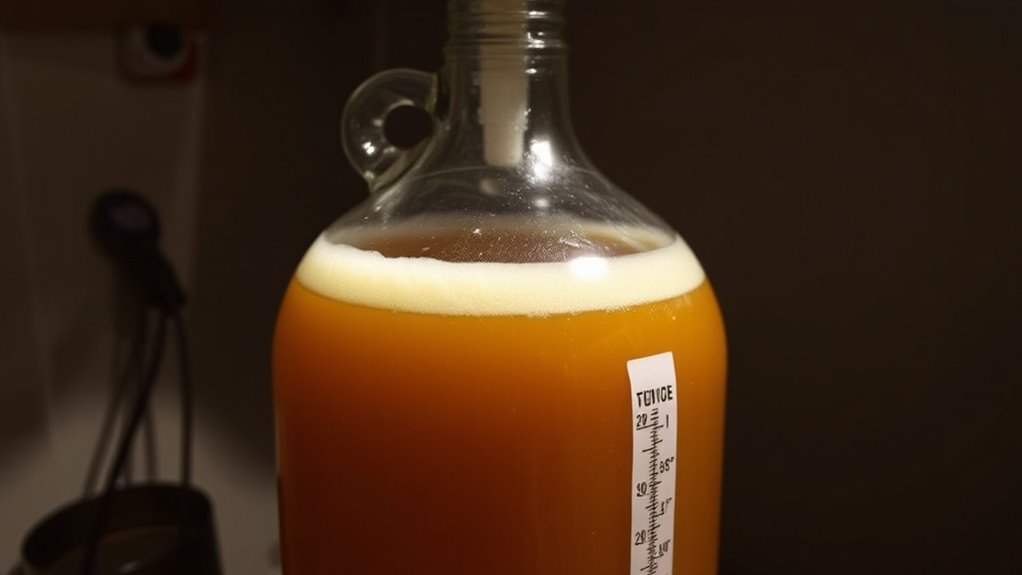

When you set up fermentation, it’s crucial to grasp how airlocks function, as they play an important role in the process. Airlocks allow carbon dioxide to escape while keeping outside air and contaminants at bay.

You might notice varying airlock bubbling depending on the design, with 3-piece and S-style models exhibiting different gas release efficiency. Keep an eye on signs of fermentation, like krausen or foam, since airlock activity isn’t the only indicator. Additionally, understanding airlock product selection is vital to ensuring optimal fermentation conditions.

Confirm your seals are tight; if they’re not, gas can escape without bubbling. Also, maintain ideal fermentation temperature for successful results.

Helpful Hints:

- Monitor fermentation signs regularly.

- Choose the right airlock type.

- Maintain tight seals.

Common Causes of Stalled Fermentation

Stalled fermentation can be a frustrating experience for any home brewer or winemaker. Several common causes can lead to this issue.

- Completed Fermentation: If your fermentation process has finished, excess CO2 production stops, resulting in no bubbling.

- Seal Issues: An improperly sealed fermenter may allow CO2 to escape unnoticed.

- High Sugar Content: If the must is too sugary, yeast can become overwhelmed, leading to a stall.

- Temperature Fluctuations: Low temperatures can slow yeast activity, affecting fermentation progression.

- Oxygen and Nutrient Deficiency: Insufficient oxygen or lack of nutrients can hinder fermentation and airlock activity. Maintaining a consistent temperature is crucial to prevent stalls and ensure healthy yeast activity.

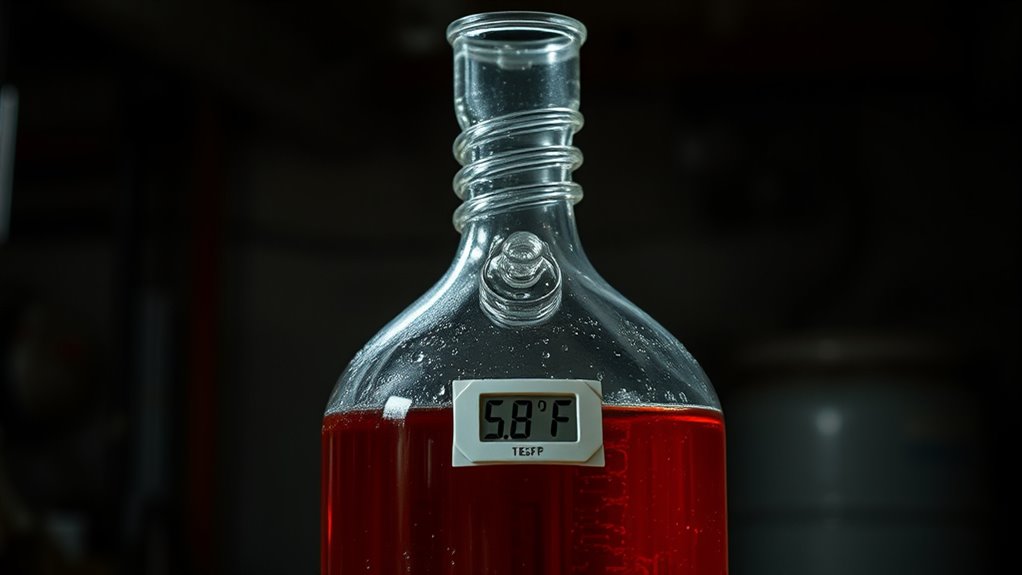

The Importance of Temperature Control

Temperature control plays an essential role in the fermentation process, as it directly affects yeast activity and the overall quality of your brew.

Temperature control is crucial in fermentation, impacting yeast activity and the quality of your brew.

To achieve peak fermentation, consider these factors:

- Maintain a consistent ambient temperature, ideally between 65°F to 75°F for ales.

- Avoid temperature fluctuations that can lead to stalled fermentation or off-flavors.

- Use heat pads or belts in cooler environments to keep dry yeast active.

Monitoring room temperature with a stick-on thermometer provides valuable insights, allowing you to adjust conditions effectively. Additionally, maintaining a stable strain-appropriate temperature range ensures yeast health and optimal fermentation performance.

Assessing Yeast Health and Activity

Evaluating yeast health and activity is essential for successful fermentation, as yeast is the driving force behind the process.

Yeast viability directly impacts fermentation; if your yeast is old or improperly stored, you might see little to no airlock activity.

Verify your fermentation environment is ideal, as temperature fluctuations can hinder yeast performance.

During initial fermentation stages, adequate aeration and nutrient addition are important.

If you notice stalled fermentation, consider re-pitching fresh, healthy yeast to rejuvenate the process. This action can restore airlock bubbling, indicating active fermentation and healthy yeast. Ensuring proper yeast management practices will further enhance the likelihood of a successful fermentation.

Helpful Hints:

- Store yeast properly.

- Monitor temperature closely.

- Aerate your mixture.

Monitoring and Measuring Specific Gravity

When you’re fermenting, monitoring and measuring specific gravity (SG) is essential for understanding how your fermentation is progressing. Here are three helpful hints:

- Use a hydrometer to take initial and consecutive SG readings.

- A stable SG over a few days indicates fermentation is complete.

- If there’s no foam, even check the SG to confirm the yeast is active.

Establish a baseline with your starting SG, typically around 1.080 for mead.

Lower SG values in subsequent readings reveal sugar conversion, helping assess fermentation efficiency and alcohol content. Additionally, understanding Alcohol By Volume (ABV) calculations can provide insight into the alcohol content produced during fermentation.

Accurate SG measurements guarantee your fermentation process is on track.

Troubleshooting Contamination Risks

Fermentation is a delicate process, and maintaining a clean environment is essential to achieving the desired results.

Fermentation requires precision; ensuring a sanitary environment is crucial for successful outcomes.

To troubleshoot contamination risks, always push down on the lid and check for a tight seal before inspecting the airlock. If you notice excess CO2 escaping, it could signal a compromised seal, allowing outside air to introduce unwanted microorganisms.

Be vigilant for off smells, especially if it smells like sulfur, which can indicate spoilage. Regularly sanitize your equipment, and monitor for surface films. Effective sanitization methods are crucial to reducing contamination risks and ensuring your fermentation remains uncontaminated.

If no airlock bubbling occurs over time, it’s vital to act quickly to safeguard your fermentation’s integrity.

Helpful Hints:

- Always sanitize tools.

- Inspect seals frequently.

- Note any unusual odors.