Cleaning fermentation vessels between brew batches is essential for preventing contamination and ensuring quality beer. Leftover yeast, hops, and bacteria can spoil your brew and negatively impact flavor. Residual Lactobacillus can produce unwanted sourness, while other contaminants can alter aromas. Use a homebrew-safe cleaner and sanitizers like iodophor after thorough cleaning to eliminate these risks. Regularly inspect your equipment for integrity. By developing a consistent cleaning routine, you can improve your brewing outcomes—more tips await to help you perfect your process.

At a Glance

- Cleaning eliminates leftover yeast, hops, and grains that can spoil future batches.

- Prevents harmful microorganisms like Lactobacillus from ruining beer flavor and quality.

- Reduces the risk of cross-contamination that negatively impacts flavor profiles.

- Enhances yeast effectiveness during fermentation by maintaining clean environments.

- Prolongs the life of brewing equipment through regular maintenance and sanitation.

The Role of Cleanliness in Brewing Success

When you brew beer, cleanliness plays a crucial role in ensuring your success.

Clean fermentation vessels are essential for eliminating leftover yeast, hops, and grains, which can lead to bad beer. By thoroughly cleaning and sanitizing your equipment, you prevent harmful microorganisms like Lactobacillus from ruining your batch with off flavors.

Clean fermentation vessels are vital to eliminate leftover yeast and grains, preventing harmful microorganisms from spoiling your beer’s flavor.

Failing to clean can cause cross-contamination, negatively impacting your beer’s flavor profile. Use homebrew-safe cleaners and sanitizers to enhance yeast effectiveness during fermentation. Proper sanitization methods, such as heat-based sanitization, are vital to ensure all surfaces are free from harmful microbes.

Regular cleaning not only maintains hygiene but also prolongs the life of your brewing equipment, making your brewing process smoother and more rewarding.

Helpful Hints:

- Clean between batches.

- Inspect equipment regularly.

- Use safe cleaning products.

Understanding the Difference Between Cleaning and Sanitizing

Understanding the distinction between cleaning and sanitizing is essential for successful brewing.

Cleaning removes residual grains, hops, and yeast from your brewing equipment using a safe cleaner and warm water. In contrast, sanitizing focuses on eliminating remaining microorganisms that could spoil your beer.

- Clean your equipment thoroughly after each batch.

- Sanitize to prevent contamination, especially with new ingredients.

- Regular inspections for residue guarantee quality. Additionally, effective sanitizing methods such as using chemical sanitizers can help ensure that your equipment is free from harmful bacteria.

Common Contaminants in Fermentation Vessels

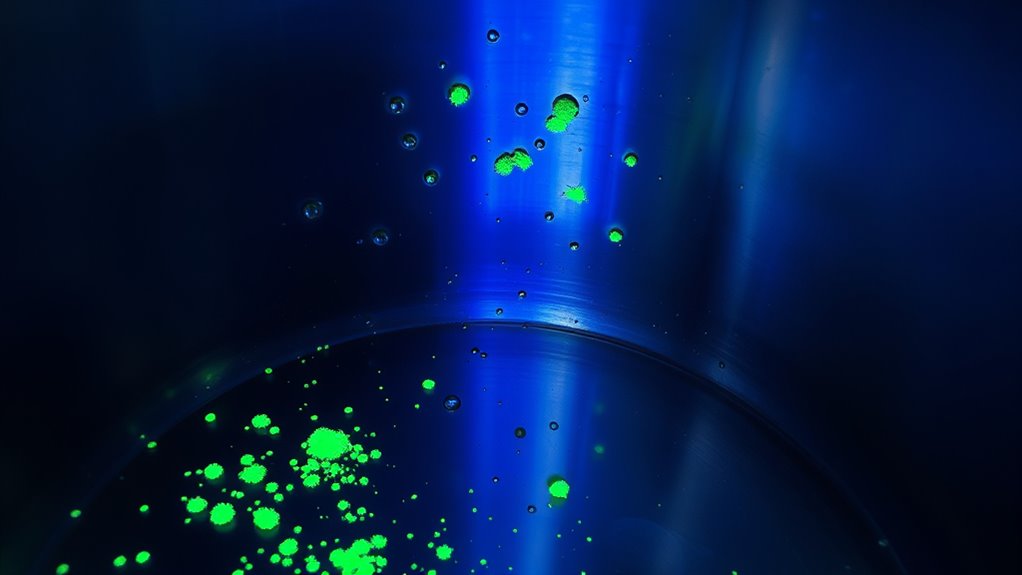

Even with the best cleaning practices, fermentation vessels can still harbor various contaminants that threaten the integrity of your brew.

Common contaminants include leftover yeast, bacteria like Lactobacillus and Pediococcus, and residue from previous batches.

Lactobacillus can produce lactic acid, creating sour flavors, while Pediococcus might generate rope-like bits in your beer.

Even trace amounts of these contaminants can ruin your brewing experience.

To maintain quality, it’s essential to clean and sanitize your vessels thoroughly between brews. Thorough cleaning and sanitizing can significantly reduce the risk of wild yeast contamination.

Regular inspections and cleaning help prevent the growth of microorganisms, ensuring your next batch remains as innovative and enjoyable as you intended.

Best Practices for Cleaning Your Fermentation Vessel

Cleaning your fermentation vessel is essential for producing high-quality brews. Start by thoroughly cleaning with a homebrew-safe cleaner and warm water to eliminate leftover yeast, hops, or grains.

After cleaning, use effective sanitizers like iodophor or hydrogen peroxide to guarantee no microorganisms remain. Don’t forget to inspect all parts of the fermentation vessel, including lids and seals, for any residue.

Using essential sanitizer products can help ensure a safer brewing environment and prevent contamination.

- Regularly replace plastic fermenters showing wear or scratches.

- If reusing a yeast cake, always sanitize to avoid off-flavors.

- Maintain a consistent cleaning routine to enhance your brewing process.

The Impact of Residual Yeast and Bacteria

Residual yeast and bacteria in fermentation vessels can considerably impact the quality of your brew. When you skip cleaning, leftover yeast can create unwanted flavors, like sourness from Lactobacillus or buttery notes from diacetyl.

Contamination not only affects taste but can also alter aromas, leading to undesirable outcomes. Using a clean fermentation vessel prevents these issues, ensuring that residual hop oils or proteins don’t compromise your new batch. Regular cleaning and sanitizing reduce infection risks, helping you achieve consistent flavor profiles. Additionally, using proper sanitizer solutions during the cleaning process is vital for eliminating any lurking microorganisms. Ultimately, maintaining a clean vessel is essential for enhancing your brewing innovation and overall beer quality.

How to Maintain Your SCOBY’s Health

Maintaining your SCOBY’s health is essential for successful fermentation, as a vibrant culture guarantees better flavor and quality in your brew.

To keep your SCOBY thriving, follow these guidelines:

- Store it in a small amount of sweet tea when not in use.

- Regularly check for signs of mold or discoloration.

- Verify your fermentation jars are clean after each batch.

Tips for Effective Sanitation in Homebrewing

When brewing at home, the importance of sanitation can’t be overstated. To guarantee your fermentation vessels are clean, start by using homebrew-safe cleaners combined with warm water.

After cleaning, apply effective sanitizers like iodophor or Oxy-Pro to eliminate harmful bacteria. Remember to thoroughly rinse all cleaning agents, especially after using strong chemicals like bleach, to avoid off-flavors in future brews.

Regularly inspect your equipment for any scratches or wear, as these can harbor contaminants. Finally, dismantle parts like lids and valves to clean them thoroughly, as those areas often retain residues that impact your beer’s quality. Additionally, maintaining consistent temperature control during fermentation is crucial to prevent unwanted off-flavors.

Helpful Hints:

- Use warm water with cleaners.

- Sanitize immediately after cleaning.

- Rinse thoroughly to avoid residue.

Building a Consistent Brewing Routine

Building a consistent brewing routine is essential for achieving high-quality results in homebrewing. By establishing a cleaning and sanitation schedule, you can effectively minimize contamination risks and enhance the overall flavor of your beer.

Establishing a consistent brewing routine and sanitation schedule is key to minimizing contamination and enhancing your beer’s flavor.

- Regularly clean your brewing system after each batch.

- Use homebrew-safe cleaners and warm water for effective sanitation.

- Prioritize cleanliness to maintain equipment integrity and improve brewing outcomes.

This disciplined approach not only protects your beer’s quality but also allows you to experiment with new recipes confidently. Additionally, maintaining clean, sterilized bottles is crucial for preserving beer flavor and preventing contamination.

Implementing these practices guarantees that your brewing process remains innovative and consistently successful.