To calculate homebrewing ingredient costs, start by estimating your malt expenses, which typically range from $15 to $25 for a 5-gallon batch. Add costs for hops, which vary widely based on type, averaging $3 to $20 per ounce. Don’t forget yeast, priced between $1 and $10 per packet, and consider adjuncts like sucrose, costing about 2 cents per ounce, to lower expenses. By examining each ingredient’s price, you can accurately gauge your total production cost. You can learn more about specific factors affecting costs.

At a Glance

- Determine the cost of malt, which typically ranges from $15 to $25 for a 5-gallon batch.

- Estimate hop costs based on usage, averaging 1 to 6 ounces, with prices from $3 to $20 per ounce.

- Factor yeast prices, which can vary from $1 to $10 per packet, depending on the type chosen.

- Include adjuncts like sucrose, costing about 2 cents per ounce, to potentially reduce overall costs by 15%.

- Consider bulk purchasing options for malts and hops to benefit from lower prices and savings.

Understanding Ingredient Costs

When you’re diving into homebrewing, it’s crucial to grasp the costs associated with ingredients. Your initial investment will involve various components, with malt often costing around $1.44 for 14.5 ounces.

Buying in bulk can cut those costs dramatically. Dry Malt Extract (DME) is pricier, at 74 cents for 2 ounces. Consider adjuncts like sucrose, which only costs about 2 cents per ounce.

For a 5-gallon batch, expect ingredient costs between $15 to $25, considerably less than purchasing commercial beer. Always plan and adjust recipes based on local sourcing and seasonal availability to manage your budget effectively. Additionally, focusing on bulk purchases of base malt can significantly reduce your overall ingredient costs.

Helpful Hints:

- Buy in bulk to save money.

- Explore alternative adjuncts for cost efficiency.

- Research local suppliers for better prices.

Calculating Malt Expenses

Calculating malt expenses is essential for budgeting your homebrewing project effectively. Start by determining the cost per unit of malt, which averages around $1.44 for 14.5 ounces.

For a 5-gallon batch, expect malt costs to range between $15 and $25, depending on your ingredient choices. Specialty malts can elevate flavor, but they may also increase costs. When selecting your base malts, consider using Golden Promise for a balanced malt complexity that complements bold hop profiles.

Don’t forget to factor in weight and specific gravity for accurate calculations. Bulk purchasing could save you up to 50% on costs.

By carefully evaluating the cost of ingredients, you’ll keep your brewing beer budget on track and innovative.

Helpful Hints:

- Research local suppliers for the best prices.

- Experiment with different malt types for unique flavors.

- Keep a detailed record of expenses for future batches.

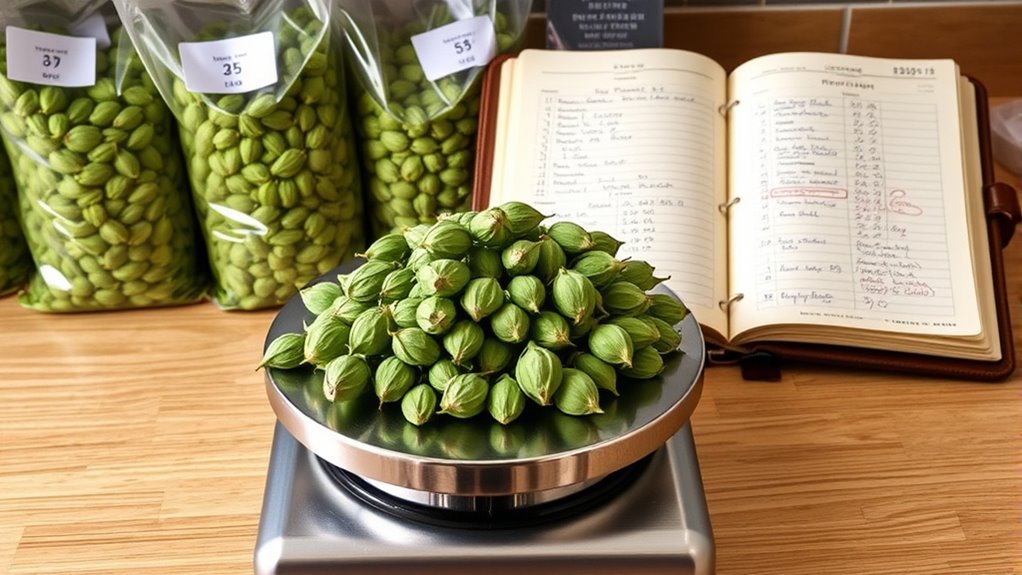

Estimating Hops Costs

Estimating hops costs is an essential step in managing your homebrewing budget, especially since prices can fluctuate greatly based on variety and availability. Hops typically range from $3 to $20 per ounce, with specialty varieties sometimes exceeding $30.

Your average hop usage for a 5-gallon batch usually falls between 1 to 6 ounces, directly affecting your ingredient costs. To save money, consider bulk purchasing; buying larger quantities often reduces the price per ounce. Additionally, purchasing hops in bulk can help ensure quality assurance by maintaining freshness for extended periods when stored properly.

Don’t forget to factor in shipping fees if you’re sourcing hops from distant suppliers, as these can greatly increase your overall expenses.

Helpful Hints:

- Research local suppliers for competitive pricing.

- Experiment with different hop varieties for flavor innovation.

- Keep track of market trends to anticipate price changes.

Accounting for Yeast Prices

Accounting for yeast prices is essential for maintaining a balanced homebrewing budget. Yeast costs can range from $1 to $10 per packet, depending on the type.

For a gallon batch, consider using dry yeast, which is often cheaper than liquid options. Repitching yeast from previous brews can greatly lower your overall yeast costs, allowing you to maximize your investment. Remember, one packet can serve multiple batches if managed correctly. When calculating total ingredient costs, don’t overlook yeast, as it can play an important role in your homebrewing expenses, especially for larger volumes. Additionally, practicing meticulous sanitation is crucial to ensure the viability and purity of your yeast, which can further enhance your brewing quality.

Helpful Hints

- Explore different strains.

- Track yeast usage efficiently.

Including Adjuncts in Your Budget

Including adjuncts in your budget can be a smart way to manage costs effectively while brewing at home. For example, sucrose costs about 2 cents per ounce, considerably less than grain-derived sugars.

Substituting up to 30% of fermentables with adjuncts like sucrose can reduce your ingredient costs by around 15%. However, be cautious; while adjuncts can lower costs, they may alter your beer’s flavor profile, resulting in a drier, more cidery taste. Additionally, consider how using different adjuncts can impact calcium levels and overall yeast health in your brewing process.

Always balance cost savings with quality, and explore local ingredient sources to enhance cost-effectiveness in your brewing budget.

Helpful Hints:

- Experiment with different adjuncts.

- Monitor flavor changes closely.

- Source locally when possible.

Water and Energy Costs

When brewing at home, understanding the costs associated with water and energy is essential, especially since these expenses can add up quickly.

Homebrewers typically use 10-15 gallons of water per 5-gallon batch, impacting water costs considerably. The energy cost, influenced by your heat source, can vary; electric brewing offers predictability, while gas prices fluctuate.

Homebrewing requires 10-15 gallons of water per 5-gallon batch, significantly affecting overall water costs.

Remember to factor in the energy needed to heat water and maintain boiling temperatures, as longer brewing processes increase consumption. Additionally, account for potential water waste during boiling and cooling stages, which can further affect your overall water cost calculation.

Helpful Hints:

- Check local water rates.

- Choose an efficient heat source.

- Minimize water waste.

Factoring in Loss Rates

Loss rates can greatly impact your brewing process and ingredient costs. To guarantee your ingredient calculations are accurate, consider these factors:

- Estimate Evaporation: During boiling, some liquid will evaporate, affecting your effective amount of ingredients.

- Grain Absorption: Grains absorb water, leading to additional loss that you need to account for.

- Calculate Actual Needs: Multiply your initial ingredient amounts by the anticipated loss rate to determine the total quantity needed.

Total Production Cost Calculation

Calculating the total production cost of your homebrew is an essential step to confirm you stay within budget and accurately assess the financial viability of your brewing endeavors.

Start by adding all ingredient costs, which typically range from $15 to $25 per 5-gallon batch. Don’t forget about hidden expenses like utilities and equipment depreciation, as these can greatly impact total production costs.

Calculate the total production cost by adding ingredient expenses, which usually fall between $15 and $25 per 5-gallon batch.

Consider bulk purchases to save on grains and hops. Finally, account for variable costs and potential losses, averaging around 10%, to make sure your budget projections are accurate. Starting with essential equipment can also help you manage initial costs effectively.

Helpful Hints:

- Track all ingredient costs.

- Factor in hidden expenses.