The five best beer heat exchangers of 2025 include the MRbrew Wort Chiller for its rapid cooling and durability, the FERRODAY 40 Plate Wort Chiller for efficient wort cooling, and the AB Plate Heat Exchanger with high capacity. The 120 Plates Heat Exchanger offers exceptional heat transfer, while the MRbrew 40 Plates model effectively cools in less time. When selecting a heat exchanger, consider factors like plate quantity, material quality, and connection flexibility to enhance your brewing experience.

At a Glance

- The MRbrew Wort Chiller features a compact design with rapid cooling capabilities, ideal for smaller brewing setups with a 4.4 average rating.

- The FERRODAY 40 Plate Wort Chiller offers lightweight handling and quick wort cooling, though it requires water hose connections.

- The AB Plate Heat Exchanger utilizes SS316L stainless steel for high-capacity cooling without electricity but may have installation instruction issues.

- Models with 40 to 120 plates provide superior heat transfer, decreasing cooling time and enhancing yeast health in the brewing process.

- Quality materials like food-grade stainless steel and copper are essential for durability, longevity, and efficient heat exchange in beer production.

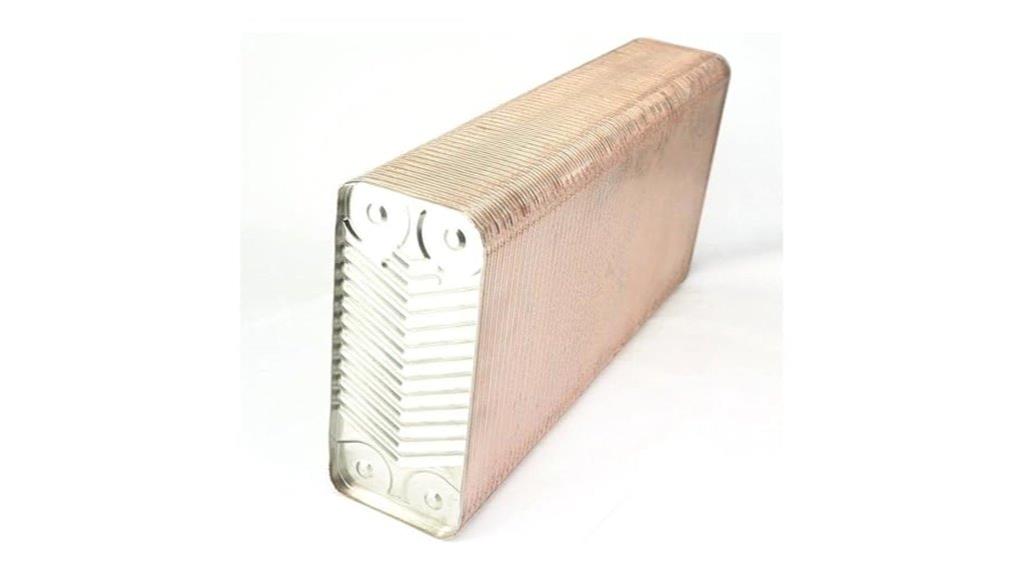

MRbrew Wort Chiller, Brazed Plate Copper Heat Exchanger for Homebrew

If you’re a homebrewer looking for an efficient way to cool your wort, the MRbrew Wort Chiller is a top choice for 2025. This chiller features a 20-plate brazed plate copper heat exchanger, maximizing surface area for rapid cooling. With dimensions of 7.5 x 2.9 inches and a 1/2 NPT thread connection, it cools wort faster than traditional immersion chillers. Constructed from rust-free 304 stainless steel, it’s built to last and easy to clean. Plus, the quick disconnect fittings enhance flow rates, making it user-friendly. It’s backed by customer satisfaction, boasting an average rating of 4.4 out of 5 stars.

Best For: Homebrewers seeking an efficient and reliable solution for rapid wort cooling during the brewing process.

Pros:

- Efficient cooling with a 20-plate design that saves time and reduces water usage.

- Durable construction from rust-free 304 stainless steel, ensuring longevity and reliability.

- User-friendly with quick disconnect fittings that enhance flow rates and simplify cleaning.

Cons:

- Requires regular cleaning to prevent metal debris buildup, which may be an additional maintenance task.

- Higher initial cost compared to traditional immersion chillers.

- May not be suitable for very small-scale homebrewing setups due to its size and design.

FERRODAY 40 Plate Wort Chiller for Homebrewing

The FERRODAY 40 Plate Wort Chiller stands out as an excellent choice for homebrewers seeking efficiency and speed during the brewing process. With 40 brazed plates, this compact heat exchanger cools wort quickly, reducing the time from boiling to fermentation in just minutes. Weighing 4.14 pounds, it’s surprisingly lightweight for its power. You’ll appreciate the upgraded 1/2 barb fitting that makes setup a breeze, along with four clamps for secure, leak-free connections. Made from food-grade 304 stainless steel and copper, it’s easy to maintain. Just flush it with a cleaning solution and clear water, then dry before storage for ideal use.

Best For: Homebrewers looking for a fast, efficient, and easy-to-use wort chiller to enhance brewing quality.

Pros:

- Quick cooling of wort from boiling to fermentation in minutes, improving brewing efficiency.

- Compact design with lightweight construction for easy handling and storage.

- Made from food-grade materials ensuring high-quality and safe brewing.

Cons:

- Not compatible with viscous liquids, requiring a filter to prevent clogging.

- Requires water hose connections which may limit portability options.

- Initial setup may be unfamiliar for first-time users without prior experience with wort chillers.

AB Plate Heat Exchanger, 3×8 30 Plates

Engineers and DIY enthusiasts looking for a reliable heat exchanger will find the AB Plate Heat Exchanger, 3×8 with 30 plates, an excellent choice for its impressive capacity and efficient design. This water-to-water exchanger, made of high-quality SS316L stainless steel, can handle 200,000 to 280,000 BTUs per hour. With a maximum temperature of 482°F and a pressure tolerance of 435 PSI, it excels in durability. Its compact size allows for easy installation in various applications, including heating systems and outdoor furnaces. Plus, it comes with a one-year warranty, ensuring your investment is protected.

Best For: Engineers and DIY enthusiasts seeking a reliable and efficient water-to-water heat exchanger for various heating applications.

Pros:

- Highly durable construction with SS316L stainless steel and 99.9% copper brazing ensures longevity and resistance to high pressure and temperature.

- Compact and lightweight design simplifies installation in diverse settings, including indoor pools and heating systems.

- Operates efficiently without the need for electricity or oxygen consumption, promoting energy savings and sustainability.

Cons:

- Some users reported challenges with the clarity of installation instructions, which may hinder the setup process for inexperienced individuals.

- Limited to water-to-water applications, which may not suit those requiring other types of heat exchangers.

- The maximum pressure of 435 PSI may not be sufficient for certain industrial applications needing higher tolerances.

120 Plates Heat Exchanger Beer Wort Chiller Cooler

For home brewers looking to chill their beer wort quickly and efficiently, the 120 Plates Heat Exchanger Beer Wort Chiller Cooler is an excellent choice. Made from food-grade SUS 304 stainless steel and featuring 120 plates, it excels in heat transfer. Each plate offers a transfer area of 0.028 m², ensuring rapid cooling. It supports a flow rate of up to 12 m³/H and handles a maximum pressure of 1.6 MPa. With a working temperature range from -160 °C to +185 °C, it’s adaptable for various brewing needs. Just connect the right ports, and you’re set for peak performance.

Best For: Home brewers seeking an efficient and high-capacity solution for rapidly chilling their beer wort.

Pros:

- Excellent heat transfer efficiency due to 120 plates, resulting in rapid cooling.

- Made from durable food-grade SUS 304 stainless steel and high-quality copper, ensuring long-term usage.

- Versatile applications beyond brewing, including hot water supply and central heating systems.

Cons:

- Requires a higher flow rate of cold water for optimal performance, which may necessitate additional equipment.

- The maximum pressure rating of 1.6 MPa may limit use in certain high-pressure systems.

- Installation may require specific fittings (1/2 BSPT and 1 BSPT) that may not be standard in all home setups.

MRbrew Wort Chiller 40 Plates for Homebrew

Homebrewers seeking an efficient cooling solution will appreciate the MRbrew Wort Chiller with its 40 plates designed for rapid wort cooling. This compact unit, measuring 7.5 x 2.9 inches and weighing 4.55 pounds, uses a 1/2 barb fitting for easy connection. By maximizing surface area, it cools wort much faster than traditional immersion chillers, reducing cooling time from hours to minutes. You’ll also save water as it aerates the wort and eliminates the need for CO2 canisters. Built from durable 304 stainless steel and copper, maintenance is easy, ensuring reliable performance for your homebrewing needs.

Best For: Homebrewers looking for a fast and efficient wort cooling solution to improve their brewing process.

Pros:

- Efficient Cooling: Cools wort rapidly, reducing cooling time from hours to minutes compared to immersion chillers.

- Water Conservation: Uses significantly less water and aerates wort, eliminating the need for additional aeration equipment.

- Durable Construction: Made from rust-resistant 304 stainless steel and pure copper, ensuring long-lasting performance and easy maintenance.

Cons:

- Requires Barbed Fitting: May need specific hose fittings, which could require additional purchases for compatibility.

- Limited Size: Compact design may not be suitable for larger brewing setups or batches.

- Potential Learning Curve: Users new to heat exchangers might need time to fully understand setup and operation.

Factors to Consider When Choosing a Beer Heat Exchanger

When choosing a beer heat exchanger, you’ll want to contemplate several key factors. Cooling efficiency is essential, as well as the number of plates, which impacts performance. Additionally, think about the material quality, connection type flexibility, and how easy it is to maintain and clean the unit.

Cooling Efficiency Requirements

Choosing the right beer heat exchanger involves understanding various cooling efficiency requirements that can greatly impact your brewing process. For peak performance, you need a heat exchanger that cools the wort from boiling to fermentation temperature within minutes; this preserves flavor integrity. Look for models with more plates, as they provide a larger surface area for faster cooling. Additionally, check the maximum flow rate; higher flow rates allow you to process larger volumes of wort quickly, cutting down cooling times. Efficient designs should minimize water usage, often aerating the wort to enhance the cooling effect while conserving resources. Also, consider the construction material, like food-grade stainless steel or copper, for durability and efficiency during high-temperature operations.

Plate Quantity Impact

The number of plates in a beer heat exchanger plays an important role in its performance and efficiency. More plates typically mean a larger surface area for heat transfer, greatly reducing cooling time. For instance, a 40-plate heat exchanger can cool wort from boiling to fermentation temperature in mere minutes, whereas chillers with fewer plates might take hours. While a 20-plate design can function adequately, it usually requires more time and water. Additionally, higher plate counts improve aeration, which is essential for yeast health during fermentation, enhancing beer flavor. However, keep in mind that more plates can complicate cleaning and maintenance, making regular upkeep necessary to prevent clogging or buildup that can affect performance.

Material Quality Importance

Material quality is an essential factor in determining the effectiveness and longevity of a beer heat exchanger. High-quality materials like stainless steel and copper are ideal due to their corrosion resistance and excellent thermal conductivity. Using food-grade stainless steel, such as 304 or 316L, guarantees safety in brewing applications and minimizes contamination risks. Additionally, brazed connections with 99.9% copper improve heat transfer efficiency while maintaining structural integrity under extreme pressures and temperatures. Choosing materials that can handle varying temperature ranges contributes to the reliability of the heat exchanger in different brewing conditions. Regular maintenance and thorough cleaning of these materials can prevent buildup, extending the lifespan of the heat exchanger and guaranteeing consistent performance over time.

Connection Type Flexibility

When evaluating beer heat exchangers, flexibility in connection type plays a significant role in how well the unit integrates with your brewing setup. The connection type impacts compatibility with different hose sizes and fittings. Upgraded barb fittings simplify setup and guarantee leak-free connections with standard hoses. Besides, if you opt for a model with male NPT threads, it allows for easy integration with various brewing equipment. This flexibility enhances your installation options. Additionally, compatibility with pumps can improve flow rates, making it simpler to transfer wort and optimize cooling efficiency. Don’t forget to take into account the inlet and outlet port sizes, as they directly affect the heat exchanger’s performance and efficiency in cooling applications.

Maintenance and Cleaning Needs

Effective maintenance and cleaning of your beer heat exchanger are essential for guaranteeing its performance and longevity. Regular cleaning prevents metal debris buildup, which can affect both efficiency and potential contamination. To maintain peak performance, many models recommend running a cleaning solution through the system, followed by clear water for thorough sanitation. Look for heat exchangers designed with easy-to-clean features, like smooth threads or removable components, which simplify the maintenance process. Additionally, materials such as 304 stainless steel and pure copper enhance durability and rust resistance, reducing how often you need to clean. Always follow manufacturer guidelines to guarantee your heat exchanger operates efficiently and lasts longer, making routine maintenance a priority for successful brewing.

Frequently Asked Questions

How Do I Clean and Maintain My Beer Heat Exchanger?

Cleaning and maintaining your beer heat exchanger is essential for peak performance. First, disconnect it and rinse it thoroughly with hot water to remove any residue. Then, use a mild detergent or cleaner specifically designed for brewing equipment, scrubbing gently with a soft brush. Rinse well to eliminate any cleaning agents. Finally, inspect for any signs of wear or blockage. By keeping it in top shape, you’ll guarantee a great brew every time.

What Temperature Range Can These Heat Exchangers Handle?

Most beer heat exchangers can handle a temperature range of 32°F to 212°F (0°C to 100°C). This range allows for efficient cooling and heating processes necessary for brewing. When you’re selecting a heat exchanger, consider its capacity to manage these temperatures for peak performance. If you operate outside this range, you might risk damaging the unit or affecting the quality of your beer. Always make certain it’s suited for your specific brewing needs.

Are There Any Safety Concerns Related to Using Heat Exchangers?

Yes, there are safety concerns related to using heat exchangers. You should always guarantee that the units are well-maintained and monitored for leaks, as any fluid escape can pose health risks. Additionally, make certain the materials used are appropriate for the temperatures and pressures involved, preventing hazards like corrosion or failure. Always follow manufacturer guidelines to guarantee proper installation and operation, reducing the chances of accidents and ensuring safety during use.

Can I Use a Heat Exchanger for Other Beverages?

Yes, you can use a heat exchanger for other beverages. These devices are designed to transfer heat efficiently, making them suitable for various liquids, such as juices, wine, or coffee. Just verify the materials are compatible with the beverage to avoid contamination. You’ll also want to take into account the specific temperature and pressure requirements of the drink you’re processing to maintain quality. Overall, heat exchangers offer versatility beyond just brewing beer.

What Is the Average Lifespan of a Beer Heat Exchanger?

A beer heat exchanger typically lasts around 10 to 15 years, assuming you maintain it properly. Regular cleaning and inspections help guarantee it runs smoothly, preventing issues like corrosion or scale buildup. If you treat it well, you’ll keep it in great shape for a long time. However, factors like usage frequency and brewing methods can affect its lifespan. So, take care of it, and it’ll reward you with consistent performance.